|

|

- Home »

- About Us

About Us

1983

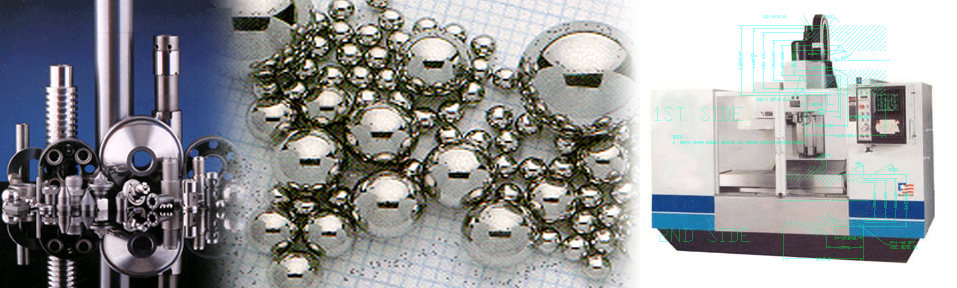

Machining Technologies, Inc. established its Wear Parts business in Elmore, Ohio,

specializing in the precision grinding of tungsten carbide wear materials. We began

catering primarily to the high-pressure paint and oil industries’ needs for fluid

dispensing and pump components such as valve seats.

1990

The Plastic Ball Division was established incorporating mold making, injection molding,

and specialty ball grinding/finishing. Plastic Balls are custom made for many applications

such as pump and flow control devises, light load bearings, construction of office

furniture and medical equipment, and are used extensively in pharmaceutical, medical

diagnostic, food and chemical production.

1991

Machining Technologies expanded by building a new facility at 468 Maple Street.

1992

This year witnessed the start of our Precision CNC Machining Division. Utilizing

state-of-the-art CNC Turning, CNC Vertical Machining, and Multi-Spindle Screw Machines

the Machining Division has the capability to manufacture just about any type of

precision machined part. Many of our customers had needs for the carbide wear components

to be brazed to parts machined from steels and other materials. The addition of

the Machining Division enabled us to autonomously produce a completed assembly in

house.

1993

This year marked the setting up of our Metal Ball Division to produce tungsten carbide

balls to compliment our Wear Parts and Plastic Ball business. Tungsten Carbide Balls

are on the other end of the hardness spectrum in comparison to Plastic Balls. They

can be found in heavy machinery applications where extreme hardness must be accompanied

by high resistance to wear and impact. Particularly, they are used in many of the

Wear Parts we produce such as industrial sprayers and flow control devises. They

are also the preferred choice for precision hydraulic valves, high load bearings,

gauging and checking instruments, and hole sizing.

1994

Machining Technologies added to its existing facility, doubling the available square

footage.

1995

Automated pressing, preforming (soft machining), and sintering technology was developed

for a Carbide Manufacturing Division to produce the cemented tungsten carbide blanks

for our Wear Parts and Tungsten Carbide Ball manufacture and the needs of other

customers for carbide blanks.

2002

The Carbide Manufacturing was shifted to Duncan, South Carolina in a bid to heighten

our expertise and increase our product base. Machining Technologies also increased

capacity by 100% through the acquisition of equipment and technology at the South

Carolina facility.

2011

Machining Technologies continues to consistently develop technology to enhance its

in-house manufacturing capabilities. We are looked upon as a leader in product development

thanks to our innate ability to closely work with our customers' engineering staff.

Most importantly, it is our Quality, Innovated Technology, and Service that have

kept us consistently at the top with our customers.